Kinto Power designs and fabricates laminated copper shunts using a wide range of the highest quality materials with standard NEMA hole patterns or custom hole patterns and various sizes for the most rigorous high current production demands.

Custom Shunt Fabrication

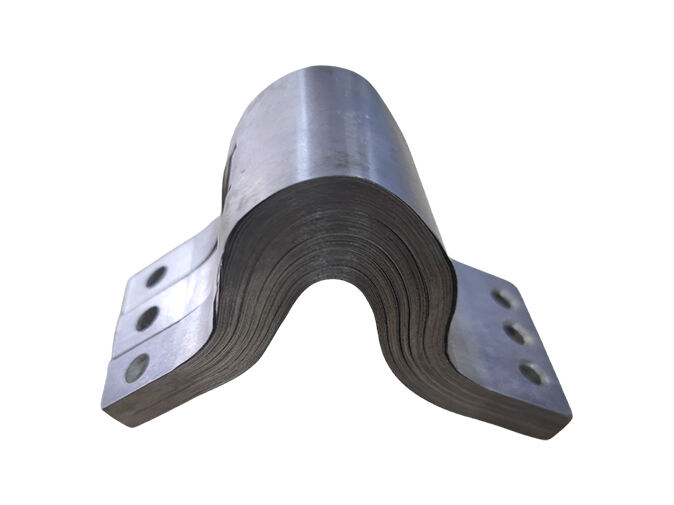

Kinto custom manufacturers copper laminated flexible shunts with resistance values on par with standard copper bar. Our shunts cover the full range of ampacity needs, serving as an ideal solution for complex installations often with minimal space. Plus laminated copper shunts are just as effective as a rigid bar in preventing current imbalance and voltage loss.

Kinto's laminated copper electrical shunts are made of several thin layers of laminated copper press-welded to create bonded ends. The hardened solid-like ends can be drilled or machined to create exact-size holes to enable the shunts to be specified and installed like any standard copper connector.

Bare Copper

Tin Plated Copper

Silver Plated Copper

Nickel Plated Copper Laminate, Terminals and Contact Surfaces

Insulation Covers (PVC, Teflon, Fiberglass)

Laminated Shunt Types

Press-Weld

Swaged

Riveted

Solder Dipped ends

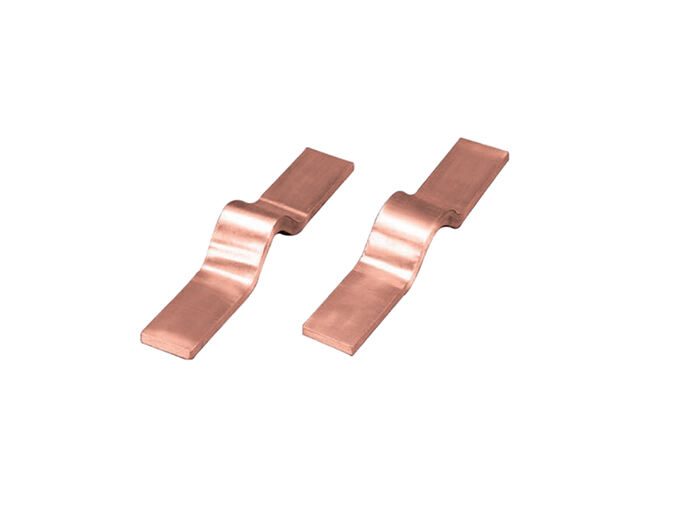

Copper Clips or Plates

Power plants

Transformers

Substations

Large motors

Generators

Switchgear

Copyright © Kinto Electric Co., Ltd All Rights Reserved