Consider how electricity makes its way from a power plant to your home. So, the answer is — copper bus bars. Bus bars are really important, as it helps to transport electricity from one place to another safely and efficiently. Their work is essential to ensure that the power remains and indeed does not dissapear somewhere along the process. If not for copper bus bars, we would find it difficult to supply power to our homes and businesses.

Why Copper Bus Bars Help to Power Strength

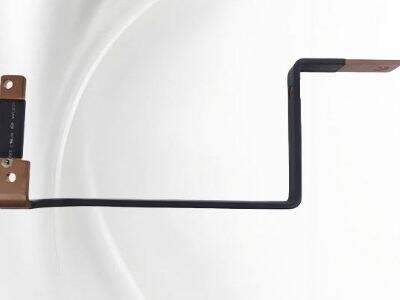

Copper bus bars represent a major component in the electrical systems that power plants use to transfer electricity to homes and businesses. These are crafted from a proprietary blended copper that is durable and has very high rust- and corrosion-resistance qualities. This is especially significant as it indicates a long float serviceable time period for the bus bars with electricity. This negative bus bar boat is because it has some unique properties that makes copper a brilliant metal for transmitting electric current.

The good thing about trolley copper bus bars is they are able to conduct a lot of current without overheating. And this is important because if they do overheat, it can lead to issues and less reliable power. Copper bus bars maintain and save energy — maintaining the strength of power, providing a reliable supply of electricity for daily consumption.

Also Read: Best Conductivity of Electricity Material: Why Copper

Then — we all know this — copper is the best metal conductor of electricity. Actually, copper is known as the best non-precious metal for electrical conductivity. This is partly because copper has very low resistance, producing very little heat when it conducts electricity. This laminated copper bus bar energy efficiency and her dependability is this property of copper bus bars.

Copper Bus Bars are processed into various shapes such as rectangles or circles while doing copper Bus bar manufacturing. The reason for this, is that different shapes can be assigned to do different jobs. And they also come in a bunch of variations and thicknesses for how much current they're expected to carry. For instance, a larger bus bar can pass more electricity while smaller ones are reserved for lighter loads. To enhance them even more, copper bus bars are sometimes plated with tin or nickel. This gives the coating which helps avoid rusting, an important factor for the longevity of operational bus bars.

Why Copper Bus Bars are Used to Reduce Power Loss

A major consideration for long distance electrical power transmission is losses, typically by heat. The further electricity travels, the more energy that can be lost on route. This loss can challenge our ability to obtain the power that we need. Because they laminated shunts copper conduct electricity with low resistance, copper bus bars prevent this loss by generating less heat and therefore wasting less energy. In this way, they assist to ensure that the majority of the energy reaches where it is intended to.

An additional key point is copper bus bars are able to withstand high temps without degradation. That means they are capable of withstanding a great deal of electrical current without overheating, which is crucial for maintaining the constancy of current upon which these power plants depend. Other materials such as aluminum may be less expensive or lighter at the same time, but they are not as conductive as copper. This implies that aluminum in electrical systems will tend to lose power over time. Since copper bus bars have a longer lifespan compared to other electrical conductors, coupled with negligible power losses during transmission, they can save individuals plenty of money in the long term.

Contribution of Copper Bus Bars to Energy Transmission

Long story short, copper bus bars play a colossal role in the safe and efficient transportation of electricity. High grade, very high conductivity & high power-handling capacity copper is used to make them. This guarantees effective, safe and nonlosing energy transmission. With energy efficency becoming more of a necessity than a luxury, copper bus bars will remain vital in providing electricity to homes and businesses across the globe.

Kinto: Manufacturing Copper Bus Bars They prioritize safety and efficiency in their product lines. Kinto bus bars are compliant with international regulations and standards. This indicates that these copper bus bars have good conductivity and low resistance. Kinto's bus bars are made of copper that is corrosion-resistant, so customers can expect to get a long service-life out of them. This is extremely critical because performance of bus bars will need to remain on par for decades.

Conclusion

Finally, copper bus bars are also very crucial for transmitting electricity to its intended destinations. Compared to other materials, such as aluminum, they conduct electricity better. Kinto designs safe, effective and durable high-quality copper bus bars. Copper busbars make it easier for consumers to get more temporary storage and reduce energy costs, improving energy efficiency, plant productivity as well as providing reliable power supply. In general, copper bus bars are a vital component to ensuring we can access electricity for our day-to-day lives.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

LA

LA