Laminated copper busbars are an exciting technology and crucial in electrical system, as well as the Kinto's copper grounding bus bar. So what are they? They are simply some unique metal pieces that move electricity from one spot to the next. These busbars are extremely vital due to the fact that, without these you would not have electrical energy supporting your home or schools and many of daily devices we make use. It goes far beyond this, laminated copper busbars are essential part of electrical systems and there are a lot of amazing benefits that come with using them on it.

Laminated copper busbars are extremely reliable and efficient, identical to busbar 400a by Kinto. Consists of multiple layers of copper laminated together form a highly strong and compact busbar. This design is perfect for use with high power levels but its utility also makes it pretty cool An overloaded busbar can impair the electrical system. However, with laminated copper busbar designs and the stresses on the electrical system are minimal so your lights stay on when you need them to operate even as systems like air conditioners come online making life much more comfortable for all.

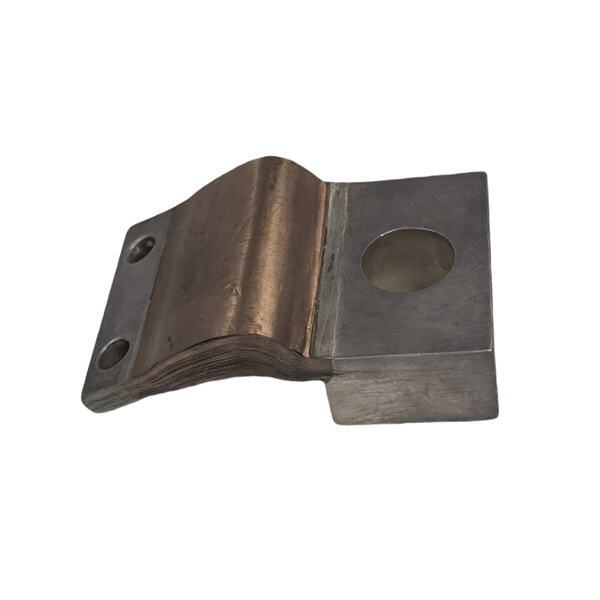

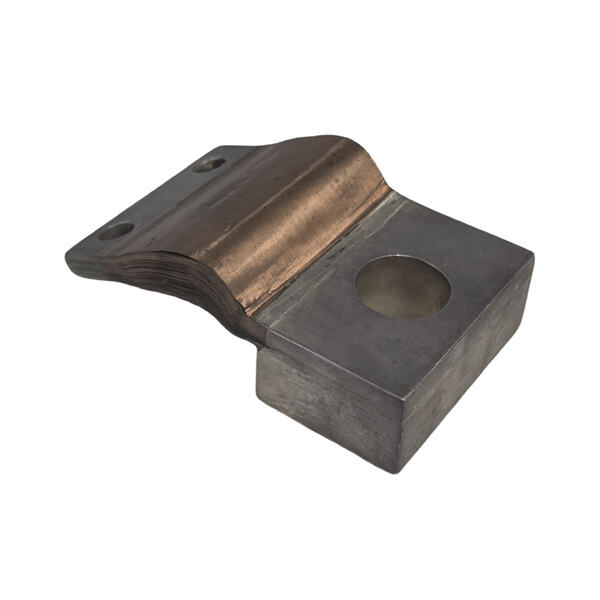

Moving on, that was the way they produce laminated copper busbars, same with Kinto's round busbar. This is made up of various laminate layers carefully stacked over one another in which copper layer. These layers are then bonded together with high pressure and heat, which results in an extraordinarily strong solid--some say more durable than the hardwood it imitates. Only a very high-energy-resistant busbar will be the final result. Moreover, this special design lower the resistance of electricity flow. Less resistance means less energy wasted, the all electrical system would have worked efficiently via consuming less electricity.

The process of manufacturing laminated copper busbar is a fascinating one with several meticulous phases involved, the same as 33kv busbar in substation manufactured by Kinto. Starting with cutting the copper into strips of just right size and thickness The strips are then placed on top of each other with adhesive layers in the middle to bond them together. When the stacks are finished, it all gets placed into a hydraulic press; basically this is just stacking them one after another and then heat pressing down on top of that with an incredibly intense pressure. This is an important part of the process because it will bond all layers generating just one robust laminated copper busbar. The busbar is then cut to size and inspected for the level of quality, that must respect some rules.

More than allowing an easy passageway for current, the unique design of laminated copper busbars does something special, as well as the Kinto's brass busbar. It also dampens vibrations and noise in the electrical system. This is crucial as decreasing vibrations and noise may be able to enhance the performance and stability of your system. Because When things are going right Al, there is a hell of lot less power outages and breakdowns - Albeit they be frustrating. Laminated copper Busbars also are capable of rust and wear better over time. That durability helps their longevity, making them a wise and dependable form of many electrical systems.

Kinto focus on cost control efficiency enhancement, through continuous optimization of manufacturing processes, reducing wasted raw materials, and improve utilization of equipment, among other ways effective cost control. The competitiveness of the raw material costs is ensured by a long-term and stable relationship supplier. In addition, it also continually introduces new technologies and equipment order to enhance processing Laminated copper busbar and product quality and reduce production costs. These steps allow us to offer our customers better competitive prices while ensuring product quality and ideal balance between cost control and market competition.

Kinto always places customer first and provides exceptional customer service to create a win-win situation. Our customer service Laminated copper busbar highly skilled and is on hand to gather and analyze customer feedback suggestions. This allows us to enhance our products and services. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is a top busbar producer Laminated copper busbar in 2005 covering 8000 square meters is committed to the development of new energy storage, transmission and distribution products, electronic appliances and communications featuring the latest technology and a wealth of production experience. Kinto has introduced latest processing equipment's and a variety of high-quality testing equipment to ensure that every product is in line with highest standards of quality requirements. The R and D team technical staff have extensive expertise and experience in providing customized solutions for a wide range complex processing requirement.

The company always puts quality of the product the first place, it's accredited through ISO 9001, ISO14001, IATF 16949, and various other certifications. To ensure consistent and reliable quality, the company controls every step procurement of raw materials to production until product inspection. It also adopts a digital management system to improve the efficiency of production and improve Laminated copper busbar. The digital management technical drawings with the EDM system ensures the accuracy and reliability of drawings. It also provides solid support for the development of products and production.

Copyright © Kinto Electric Co., Ltd All Rights Reserved