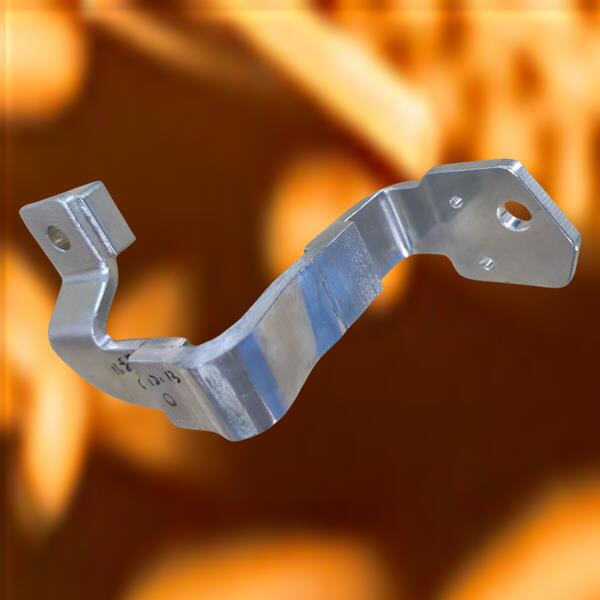

In any electrical system, and aluminum bus bar is an essential component. It appears as a thin flat piece of aluminum metal. It serves as a vital part that helps transfer electricity from one place to another in the system. Aluminum bus bars make it easier for electricity to flow where we want it too.

Aluminum bus bars are used to distribute power across a circuit board or another kind of electrical apparatus. The bus bar has a wide surface area, which makes it an excellent conductor of electrical current as I mention earlier. One of the reasons why aluminum is so good at conducting electricity is because it provides very little resistance to electrons, these are tiny particles that move around a current. During this process, electrons are moved to allow electricity to flow and devices being in function.

Aluminum bus bars bring with it a number of advantages to apply in an electrical system. The first and foremost reason is the lighter weight of aluminum serves it as a best metal to be used for bus bars. The light weight of heating tape also reduces the load from electrical systems, improving ease of handling and installation. This is also known as a bus duct or Busway and while copper is sometimes used for the metal, aluminum would be more affordable in that mass. This cost effectiveness is vital for manufacturers and builders to save money on construction. Finally, aluminum is a great thermal conductor. This means it experience has a good conduction of heat, we need that on electrical systems so to keep them safe and working long over the years.

READ MORE When your installing an aluminum bus bar in some tips are there which you must consider to avoid any inconvenience. In the first place, select correct size of bus bar. It must be rated for the total amount of electrical current that will flow through it. Selecting the wrong size could result in overheating or damage to your system. Tip 2 will keep it where you want and not flopping around. Any motion or pressure could harm the bus bar, and other parts of an electric system Finally, be sure to adhere safely procedures when mounting the aluminum bus bar. Flycut For instance Jolt Things like to power source is not turned on for installation This will avoid accidents and keep you safe while working.

Aluminum bus bars are built to last for years, however proper maintenance is a necessity and even repairs could be needed. Monthly inspections of the bus bar should be performed to ensure that it has not been damaged or corroded; Electrical issues are a symptom of things like damage or rust, which have potential for being incredibly risky to come across. Upon identifying any type of damage, make it a priority to repair or replace the bus bars which have been damaged so as they will be able to do their job efficiently. In addition, it is necessary to regularly clean the bus bar. Its conductivity will be preserved, helping it to continue connecting electricity.

Aluminum bus bars are also often thought to be unsafe but it is not true in any way. To begin with, some users feel these aluminum bus bars are not as effective when compared to the copper bus bars. However, this is not true! Aluminum bus bars are lighter and less expensive then copper, but still aluminum can serve as a good conducting material for electricity. There electric systems are thereby a perfect choice. Secondly, there is this misconception among a few that aluminium bus bars can only be used in low current electrical systems. While it is true that they are not best for high currents settings, they can still be used as long as the right size is chosen.

Copyright © Kinto Electric Co., Ltd All Rights Reserved